Stainless Steel 304L-316L grade

- On 25 August 2017

The majority of Welded Metal Meshes are made using stainless steel to DIN 1.4307 (AISI 304L) or DIN 1.4404 (AISI 316L).

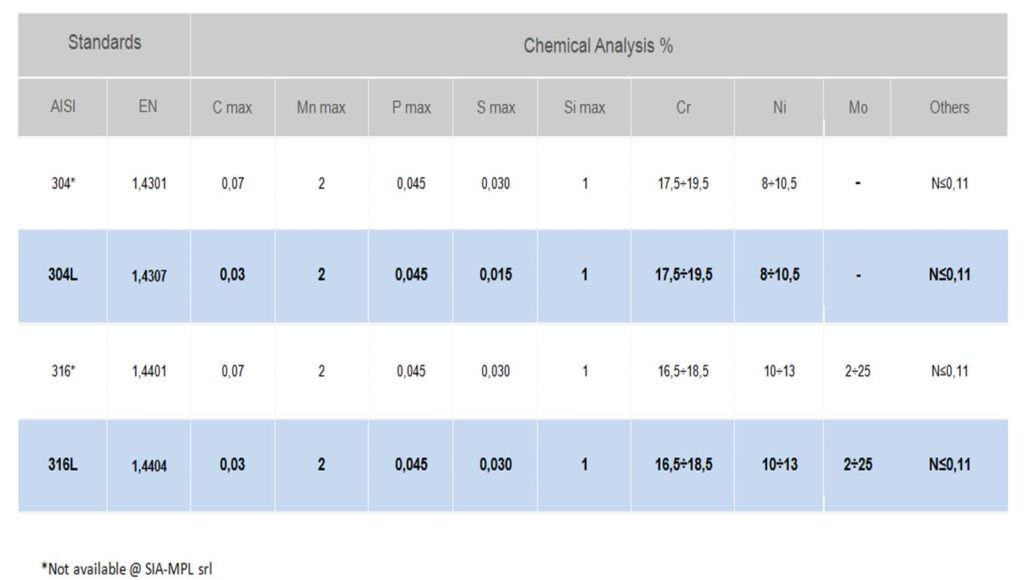

This table is an overview of the various material characteristics ad it compares 304-304L characteristic and 316-316L too, but is not a comprehensive list .

It does not contain all information about the various alloys austenitic stainless steels and ferritic stainless steels.

SIA-MPL boasts stainless steel stocks with AISI 304 and AISI 316 only in “L” grade, in order to guarantee the highest quality materials, whether for standard or customized products.

304L Grade Stainless Steel

Cr-Ni austenitic steel non-hardenable, particulary suitable for welded constructions.

Stainless steel is normally nonmagnetic in the annealed state, slightly magnetic when cold worked such as in case of mechanical wire strightening for welded mesh production .

Grade 304L has excellent intercrystalline corrosion resistance and may be used normally at temperatures of up to 425°C. It resists ordinary rusting in most architectural applications and it may be subjected to electropolishing. It is also resistant to most food processing environments, can be readily cleaned, and resists organic chemicals, dye stuffs and a wide variety of inorganic chemicals.

Typical applications for 304L include, food and beverage processing, equipment and utensils, architecture commercial and domestic kitchen construction, sinks, and equipment for chemical, petrochemical, mineral processing and other industries.

316L Grade Stainless Steel

Cr-Ni-Mo Austenitic steel non-hardenable with an extremely low Carbon content and particularly suitable for welded constructions. Its main advantage over grade 304L is its increased ability to resist pitting and crevice corrosion in warm chloride environments.

Grade 316L has excellent intercrystalline corrosion resistance in a wide range of media, due to the presence of molybdenum and may be normally used at temperatures of up to 450°C. The mechanical properties at high temperature are also better than those of similar types with molybdenum.

Typical applications for 316L include boat fittings and structural members; architectural components particularly in marine, polluted or industrial environments; food and beverage preparation equipement, particularly in chloride environments; heat exchangers; water filtration, and equipment for chemical, petrochemical, mineral processing, photographic and other industries.

Although 316L is often described as the ‘marine grade’, it is also seen as the first step up from the basic 304 grade.

Other available materials

We can produce welded wire meshes using special alloys and other materials to your specifications. Please contact us to discuss your requirements.