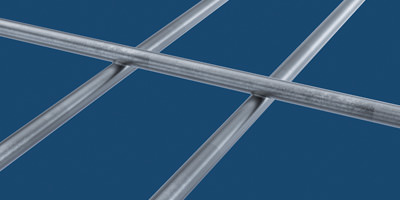

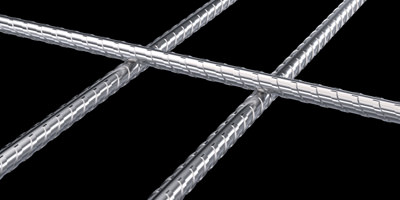

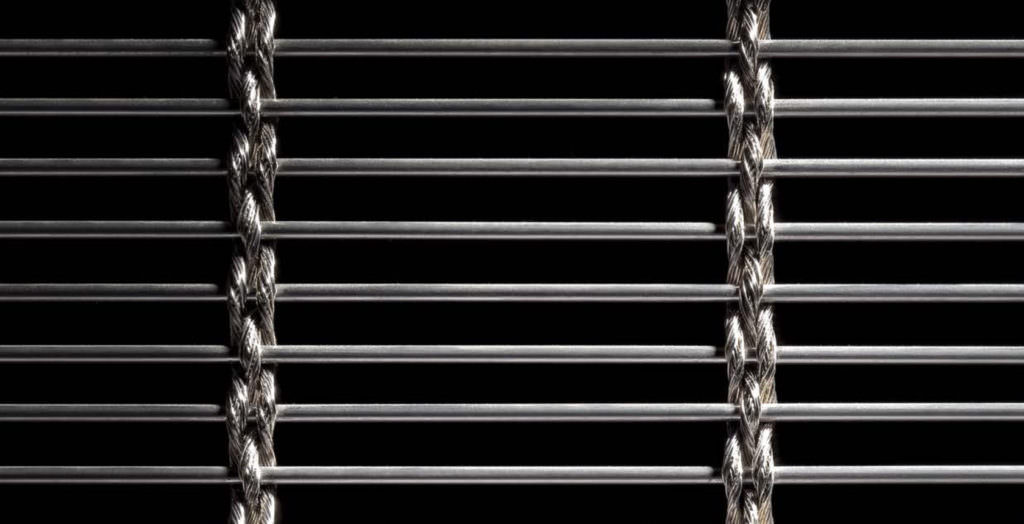

Welded wire mesh panels are obtained by welding together, with electric resistances, a series of parallel longitudinal wires to cross wires respecting accurate required spacing: the size between longitudinal and cross wires is called mesh. Longitudinal wires identify the length of the panel while transversal wires define its width.

The production of panels and rolls, available in carbon steel, stainless steel AISI 304L (EN 1.4307) and AISI 316L (EN 1.4404) and in pre-galvanised wire or zinc-aluminium, can be made from longitudinal wires coming from coils or from fitted pre-straightened bars, transversal wires always come from fitted bars.

Welded mesh is always manufactured with open edges, but on request these can be removed after production and cut off on each side of the panel. Thanks to the welding points and the rigid production tolerances, welded wire mesh is easy to work, cut, bend and paint: in addition to the standard sizes, SIA-MPL also provides personalised solutions with specific mesh types, sizes and processes.

SIA-MPL keeps a well-stocked warehouse of raw material and can guarantee short delivery time.